About Us

Company Introduction

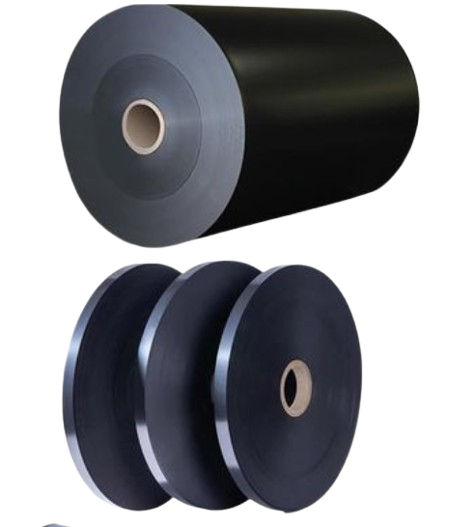

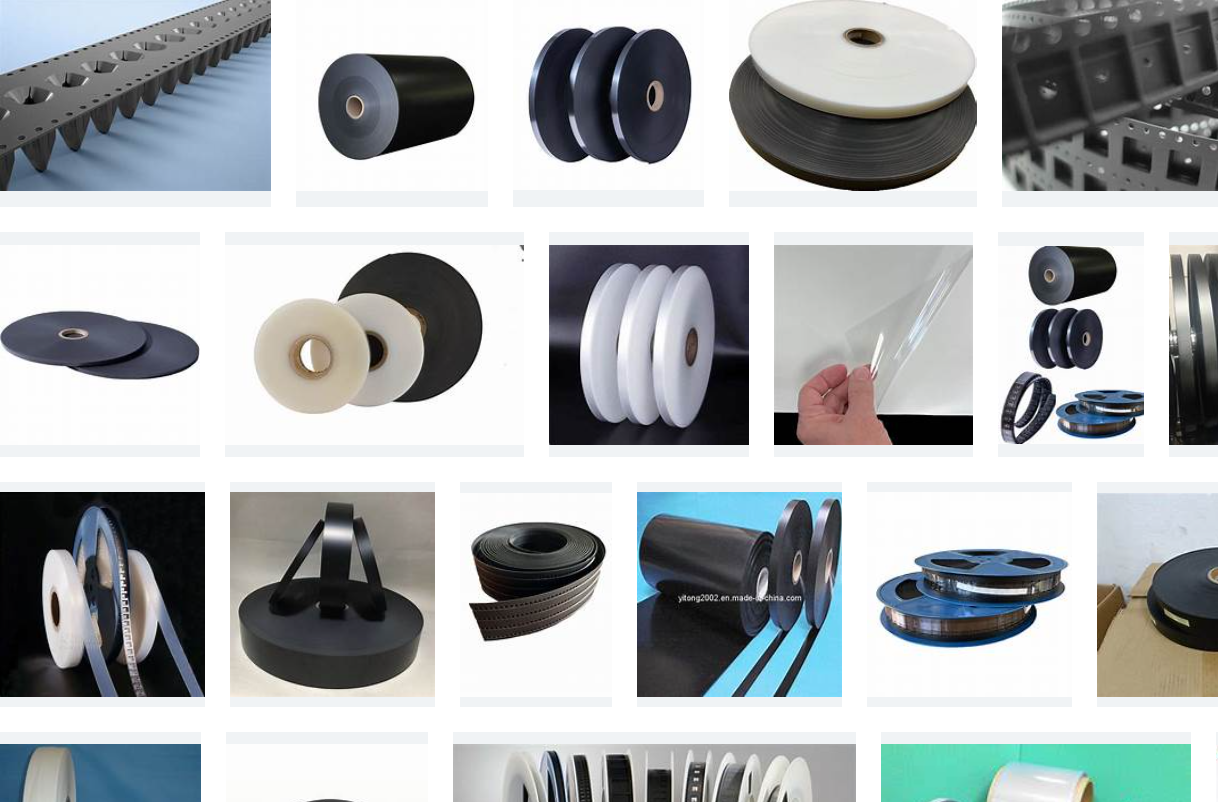

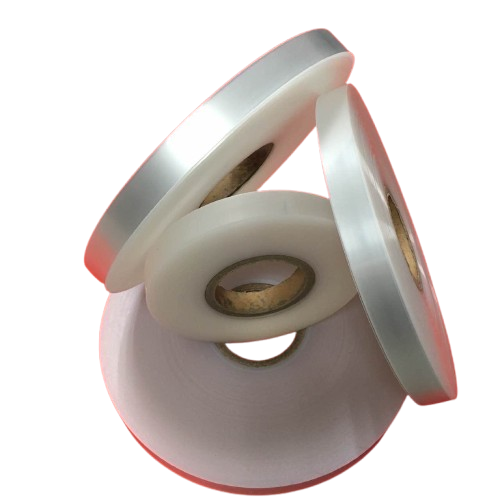

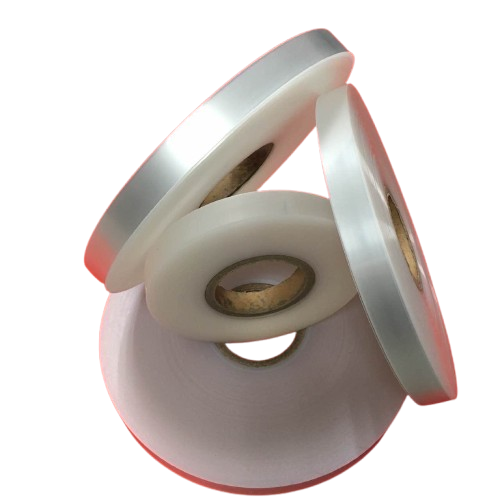

Shenzhen Hongxinxing New Materials Co., Ltd. has introduced advanced foreign technologies and possesses multiple co-extrusion production lines for manufacturing transparent permanent anti-static sheets, black permanent anti-static sheets, and conductive sheets, such as PET anti-static sheets, PET transparent sheets, PS black sheets, vacuum forming sheets, PS transparent sheets, and PS high-transparency sheets. In addition, the company also produces carrier tape leather materials, including semiconductor carrier tapes and PS conductive carrier tapes, etc. The product has excellent performance and good stability. It is known that it can reach or even exceed the standards of similar foreign products. Meanwhile, the company can also carry out customized development and design based on customer demands. In addition, the sheet materials used by the company can be matched with the heat-sealing tape and self-adhesive tape of multiple tape companies (such as 3M and Electric Card), and after matching, the tensile range is stable, which can better implement the packaging of products to achieve a perfect great effect.

Related Technology

The reasons for choosing us since 2008.

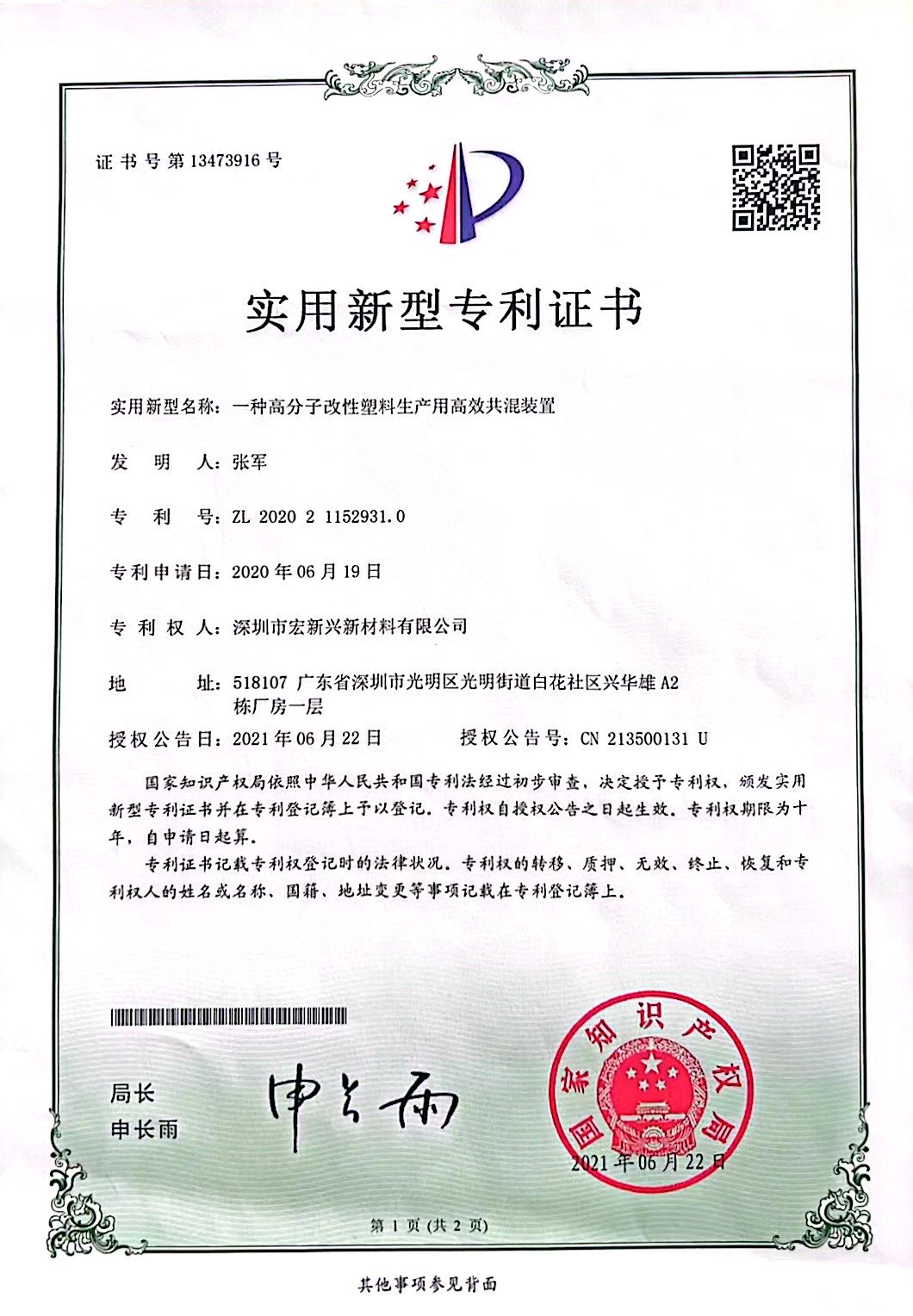

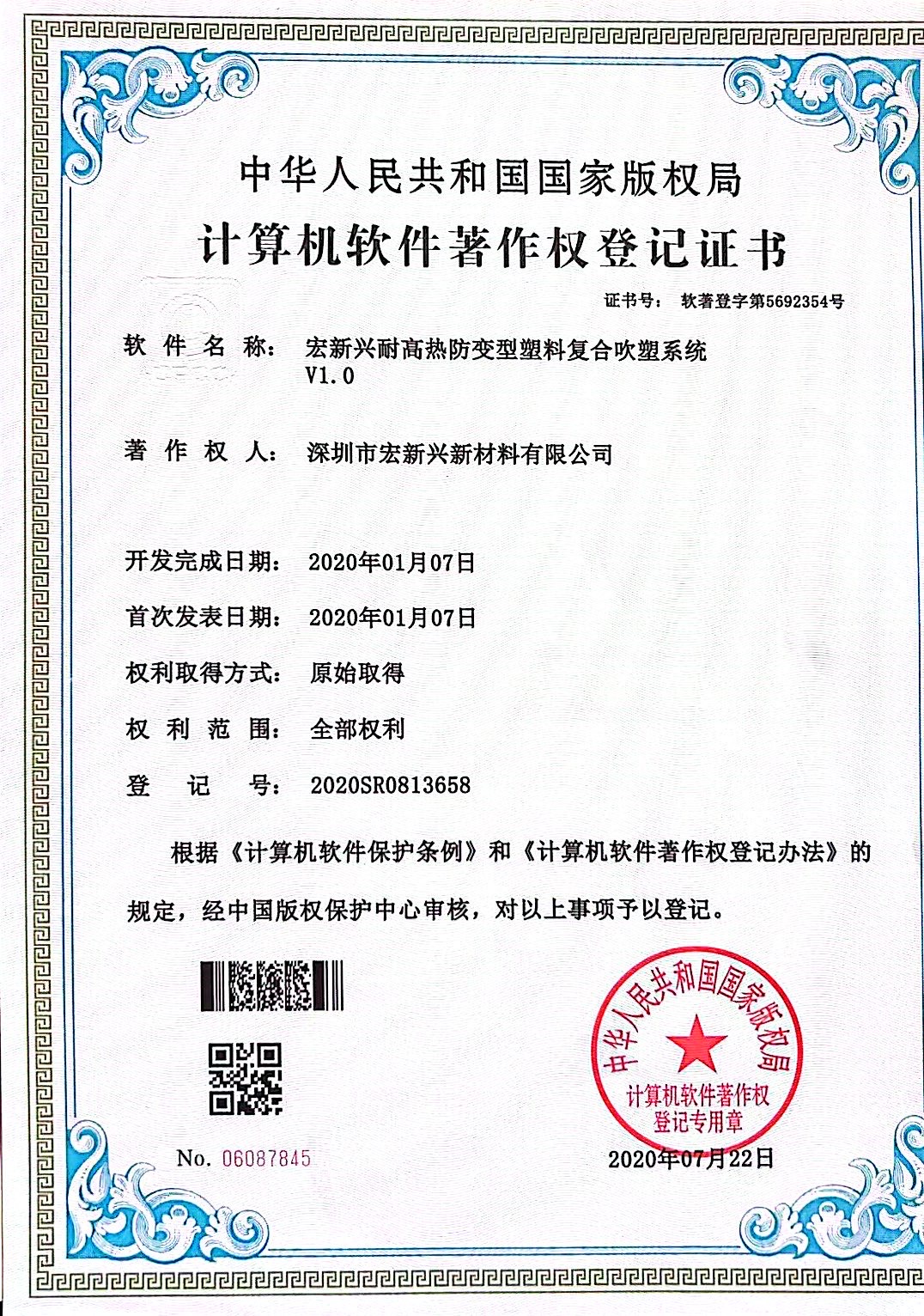

Certificate

Relevant patents and software Copyrights

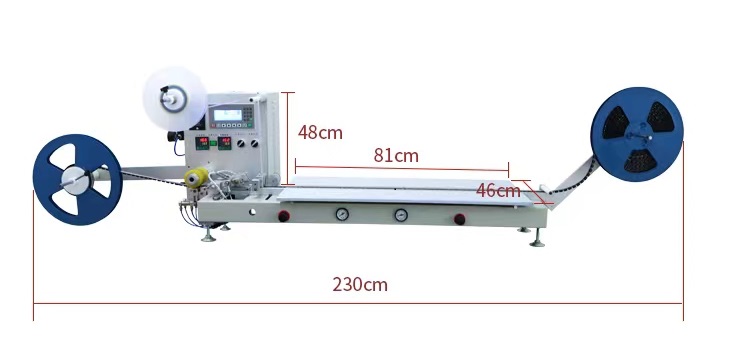

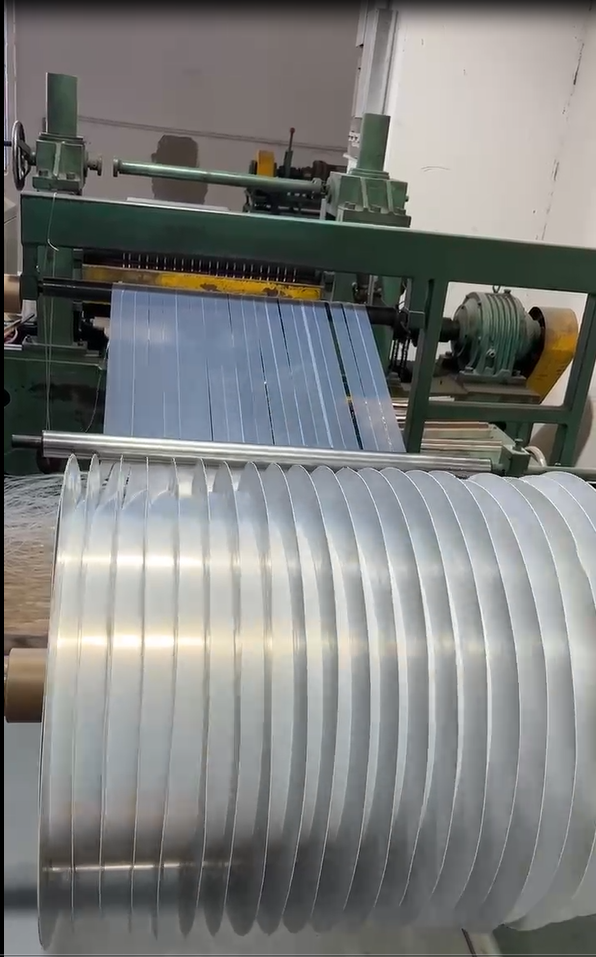

Complete production process

PS ~ High transparency

- The main differences between PS high transparency and ordinary PS lie in transparency, performance and application fields.

- Ordinary PS has a certain degree of transparency, but it is relatively low. Its appearance is slightly grayish-white and its mechanical properties are relatively brittle. It is mostly used in disposable plastic products or ordinary household appliance components and other occasions where transparency requirements are not high.

- PS high transparency has enhanced optical performance through modification technology, with a transparency close to that of glass and increased toughness. It is mainly used in products with high requirements for appearance and light transmittance, such as food packaging, cosmetic containers, and transparent lampshades.

- In contrast, PS High Transparency is slightly more expensive, but it has more advantages in fields that require high visual effects, while ordinary PS is more suitable for daily applications that are sensitive to cost.

PS ~ Black conductive

- The main differences between PS black conductive and ordinary PS lie in their electrical conductivity, application and cost.

- Common PS is an insulating material with a variety of colors, high rigidity and transparency. It is mainly used in plastic products in daily life, such as food packaging and the shells of household appliances.

- PS black conductive material is endowed with conductive or anti-static properties by adding conductive fillers (such as conductive carbon black or carbon fiber). It is generally black and is mainly used in the electronics industry where anti-static or electromagnetic shielding is required, such as anti-static trays and packaging of electronic components.

- In contrast, the production process of PS black conductive is more complex and the cost is higher, but it plays an irreplaceable role in specific fields. Ordinary PS, on the other hand, is more suitable for daily routine uses and has a higher cost performance.